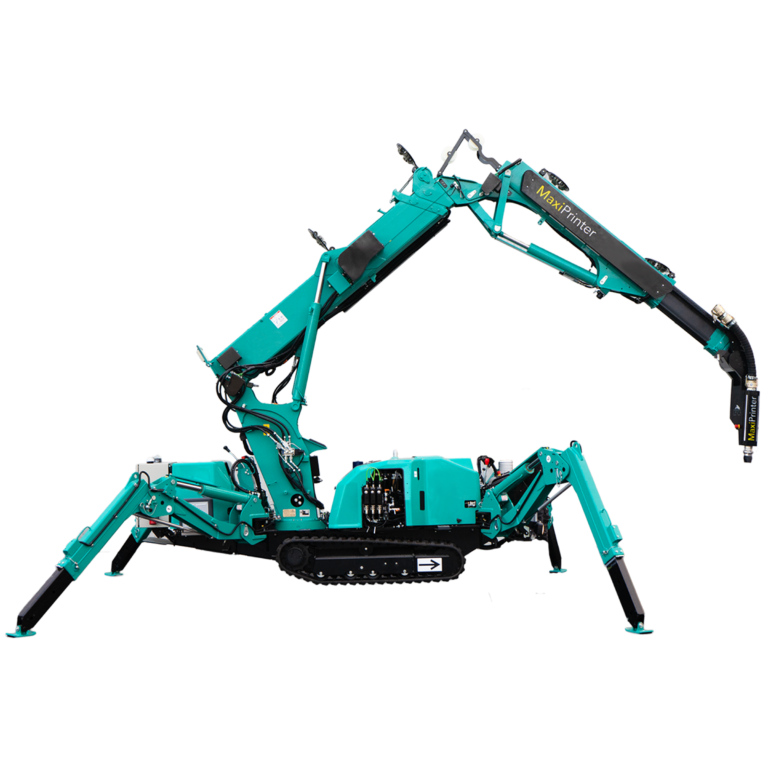

MAXIPRINTER

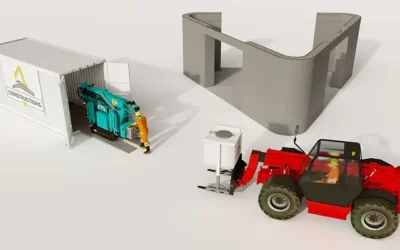

The MaxiPrinter 3D concrete printer, engineered by Constructions-3D, presents a groundbreaking solution for the construction sector, merging cutting-edge innovation with sustainability principles. Leveraging advanced technology, the MaxiPrinter enables the rapid creation of durable, tailored concrete structures.

Starting at $580 000

Excl Tax and Shipping

Starting at $580,000

excl tax and shipping

Main Features

Fast

Two-hour set up and take down

Mobile

Drives on treads. 360 in-place motion

Compact

Fits through doorways. One 20-feet container has it all

Controllable

Six points of articulation and more than twenty sensors

Precise

Repeatability level of 1mm

Economical

Small and lightweight with long reach

Unbounded

Greater design freedom upwards and outwards

All Terrain

Access outdoor, indoor, uneven, and remote sites

Start and Finish with Ease

Step 1 : Deployment and installation of the material

Step 2 : Initialization of the Printer and Pump

Step 3 : Printing

Step 4 : Cleaning and storage

we’re here to Answer all your questions

The MaxiPrinter stands out due to its precision, impressive printing speed, easy-to-use interface, and exceptional mobility.

How Does the Mobility of the MaxiPrinter Enhance Its Performance?

It moves smoothly on tracks at 2 km/h, weighs just 2.8 tons, and can print from one spot, fold up, move, unfold, and continue printing elsewhere. This flexibility provides an infinite printing area. With a small turning radius, it maneuvers easily even in tight spaces, revolutionizing on-site printing capabilities.

How does the Compact Design of the MaxiPrinter Enhance its Performance?

Firstly, its ability to fit through a standard door ensures ease of maneuverability within construction sites. Additionally, its size allows it to be transported via elevator or container, enhancing its portability and flexibility. Notably, the printer can fit into a staircase hopper for transportation to upper slabs, enabling seamless printing on multiple floors. Its dimensions, measuring 850 mm (W) x 3010 mm (L) x 1990 mm (H) (2.8′ x 10.2′ x 6.5′) further emphasize its compactness, making it ideal for transportation and project versatility.

How Precise is the MaxiPrinter?

With accuracy within 1 cm and a repeatability level of 1 mm, it ensures consistent and reliable results. Its 3D printed nozzle offers versatility with various shapes and rotation options. Path correction every 33m (108′) guarantees precise alignment, while unlimited control enables real-time adjustments for material consistency and printing speed.

Why is the MaxiPrinter an Economical Solution?

Firstly, its design eliminates the need for a crane or gantry during installation, along with the absence of formwork and console requirements, reducing setup costs significantly. Additionally, savings on insulation expenses are achieved by creating a cavity and applying bulk insulation, bypassing the need for rails and fiberglass. Moreover, the MaxiPrinter optimizes the volume of concrete used in wall construction, with a 30cm (12′) 3D-printed wall requiring 60% less concrete compared to a solid wall of the same thickness. This reduction translates to substantial material cost savings. Lastly, operational efficiency is enhanced by requiring only 1 pilot/operator and 1-2 additional personnel, minimizing labor expenses.

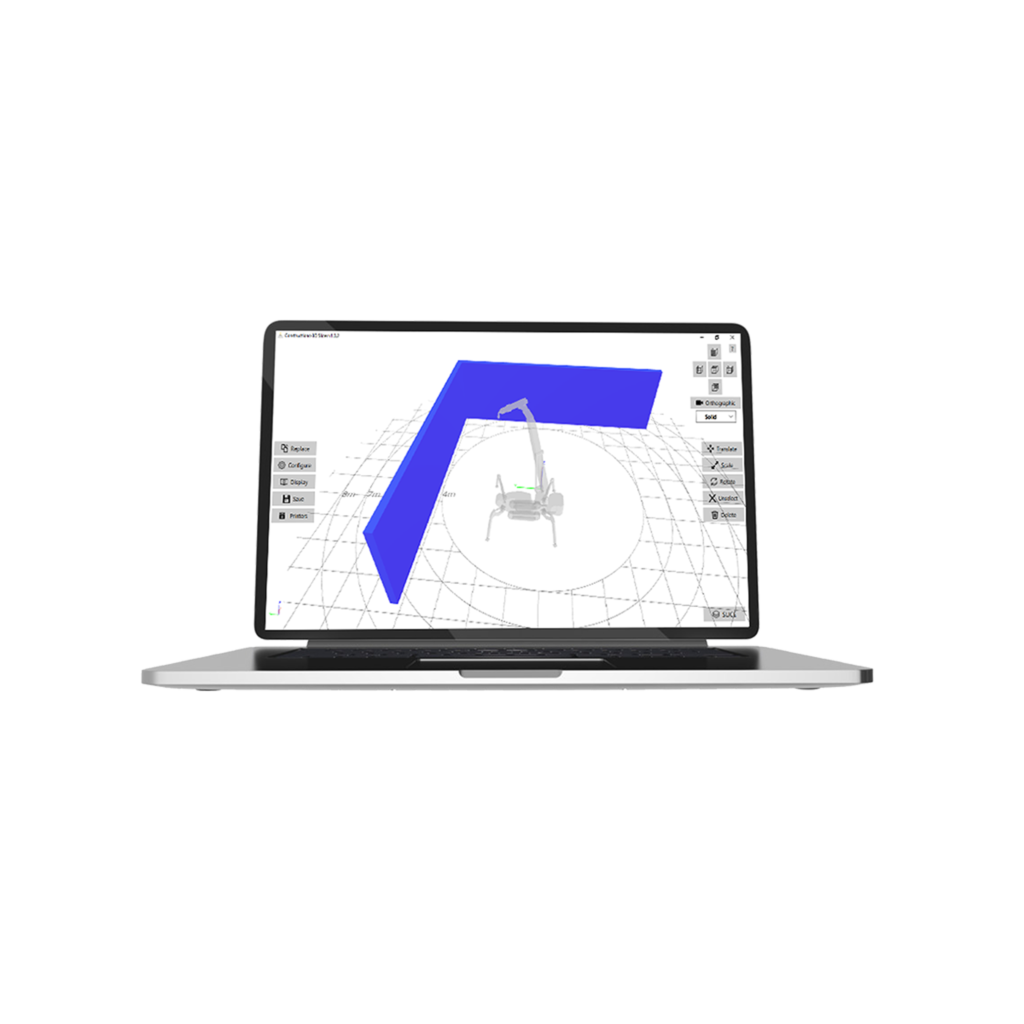

Seize Control of Your 3D Printing Journey

Its advanced control system ensures smooth and reliable printing. Its ability to work with various types of concrete offers unmatched flexibility.

⋅ 20+ sensors monitoring material pressure, humidity, oil temperature, layer time, and water flow, etc.

⋅ Maintenance and post-print feedback, and enabled adjustments like increasing water with high material pressure

⋅ Presence Of A Camera To Monitor The Progress Of The Print

⋅ Seamless connectivity between the pump and control screen

⋅ Ability to configure alerts (checkpoints) during printing

⋅ Track the progress of the print, remaining time, amount of material used, etc.

⋅ Ability to pause, stop printing and resume the next day where it stopped

⋅ Dedicated slicer perfectly adapted to our machines

⋅ software evolves and the version is updated for free and for life

⋅ Efficient remote customer service (Machine connected for updates and maintenance)

⋅ Presence of portable emergency stops

⋅ many other Safety related elements, especially on the control screen, on the nozzle head, etc.

Complete Package

(delivered in 20ft container)

MaxiPrinter

Dedicated Software

Remote Control Screen

C3D Starter Kit *

* C3D Starter Kit: pumping hose for concrete + set of pumping rotors and stators pumping stators + transport and assistance equipment

Training

triple milestone

Pavillon – 2019

Accueil – 2020

Tour – 2022

Live the experience

Partners & Clients